Dry Powder Extinguishing System

Date:2020-06-08 Click:582 Share to:

Dry Powder Extinguishing System

Specifications

Dry Powder Extinguishing System, fire suppression system, fire protection system ,fire security system

Dry Powder Extinguishing System

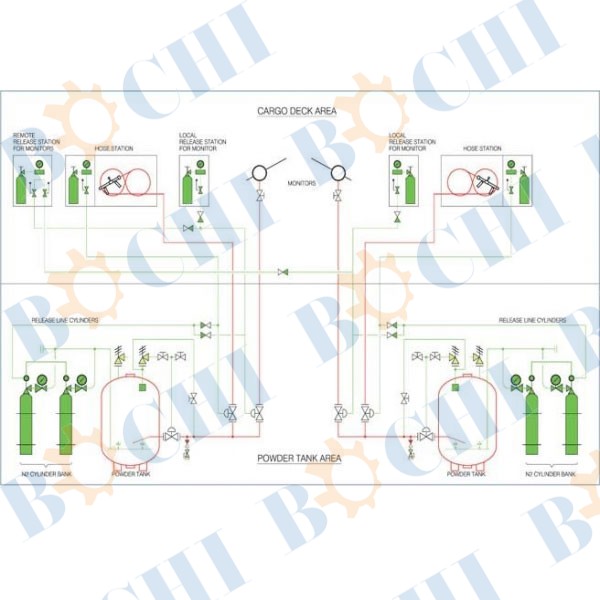

Used in cargo manifolds, deck areas and cargo holds on gas carriers.The dry powder fire extinguishing system is designed to comply with IMO Codes and in general the NFPA 17 for protection of decks and cargo manifolds on gas carriers, and tanks on chemical tankers where required.

The system extinguishes the fire using dry powder, which is ejected from monitors and hose stations using nitrogen as the propellant. The dry powder extinguishes the fire by chemically breaking the combustion cycle.

Features and benefits

Meet IMO IGC Code Chp 11-4, Class and NFPA regulationsExtensively independently tested, ensuring regulatory complianceTested and proven time release and capacity demandsA wide range of powder pressure vessels available (160 to 2500 kg)Flexible design allows monitors to meet a full range of flowsNon-kinking hoses with attached pistols provide flexible powder deliveryStandardized system components ensure easy servicingSafe and secure, proven in vessels worldwideComponents can be delivered installed on skid units

Central

Powder vessels and cylinders located centrally for distribution to monitors and pistols

Proven piping arrangements match monitor and delivery demands

Modular

Modular units provide a flexible solution and reduce pipe routes

No distribution piping required

Can be used as a part of a central system

Technical Design

The dry powder system is flexible in design and is usually delivered either as a central or modular system but in some cases also as a hybrid which is a combination of the two. Choosing either of them, they come with steel pressure vessel(s), cylinder banks with manifolds, gas release arrangements, pressure gauges and safety valves.

The central system is designed as a single or twin storage pressure vessel located centrally inside powder room. The system can be used to discharge powder across the whole cargo area at required capacity, or linked together the whole capacity can be used on a single area.The central system feed powder from the central tanks through piping systems on deck to the hose stations and monitors. The piping system is designed specifically for the vessel. Piping arrangement and flow calculation are supplied with each system.

The system uses PN16 piping between the pressure storage vessels and the hose stations and monitors. Hose stations are located on deck in a way that every part of the deck area can be reached with two hose stations. The hose stations consist of local release arrangement and 33 meters of hose with a powder pistol.

Monitors are located at both cargo manifolds and can be released locally and remotely.

In a modular system each hose station unit and monitor unit has its own self-contained powder pressure vessel.

ChatOnline

ChatOnline